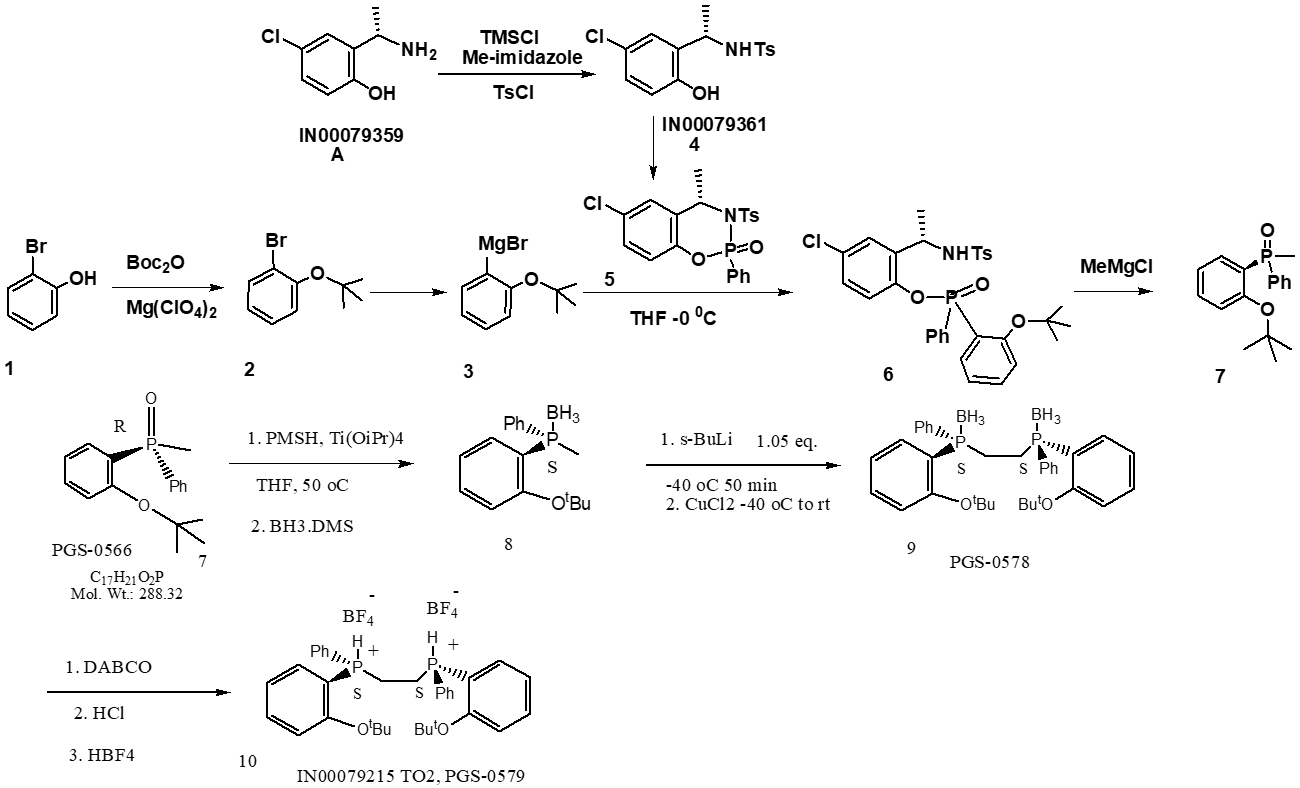

The Preparation of The Tosylate

An Optically Pure Chiral P-Ligand, Published in JOC.

Processing issues

- The preparation of the tosylate: the protection and de-protection were used.

- The tBu-OPhBr formation, in the previous process, the preoxide ester and Grignard reagent were used for the transformation. The raw materials are of high cost and the conditions are unsafe.

- Key intermediate 6, highly flammable tBuLi was used in the old process,

- which was very difficult to scale-up.

- Four flash column isolation/purification were used.

- The final ligand originally was a bis-BF4 salt, but highly instable during drying.

- Overall yield was low, 6.2% only.

PGS Major Improvements

- The synthesis of the tosylate, an in-situ protection with TMSCl was used, save 2 steps with high yield.

- PGS has changed this synthetic approach and used (Boc)2O as tBu transfer agent in the presence of catalytical amount of Mg(ClO4)2. The reaction was successfully scaled-up with ~79% yield.

- PGS made breakthrough change for the ring-openning step and eliminated the tBuLi for this step. This major improvement has been employed in this scale-up campaign with expected results.

- The isolation and purification have been simplified for entire process. Only one flash column was used for the entire process instead of three chromatographic isolations.

- The overall yield has been significantly improved from 6.2% to 12%.

- In addition to the above achievements, another significant progress is the stability enhancement of the final product. This was a typical example of the collaboration of PGS and BI, CT during this campaign. The content of HBF4% was identified as critical controlling parameter (<26%, 2.3 eq.) for the final product stability under ambient conditions. This new finding was used as guidance for this campaign and couple of protocols were developed to reduce the residual HBF4. All batches PGS delivered from this campaign have lower levels of HBF4 (~26%) then the previous batches with 30-33% of HBF4.

- A total of >1.4 kg of the final ligand was produced and delivered with high quality and good stability, ee >99.5%, Cp >98.5%.

- List Item #1

- List Item #2

- List Item #3