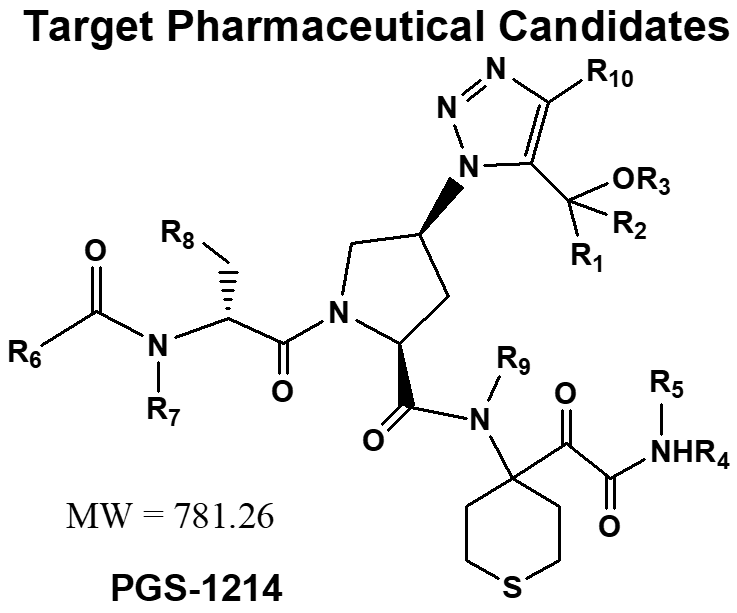

Processing and Scale-up

Processing and scale-up issues

- 4 Coupling reactions, all need flash column for isolation/purification.

- Side-chain, tedious synthesis, difficult to make it pure.

- One coupling reaction using DMTMM reagent, the reaction easily to be stalled, requires adding more coupling reagent multiple time.

- Final API, amorphous, extremely difficult to be purified, cp only 97%.

- Total 9 + 2 = 11 steps, overall yield ~8%.

Major Improvements

Steps 1-2. these two reactions were performed in one-pot fashion. The work-up and isolation was eliminated.

Step 3. After Step 2 operation, the reaction mixture was simply worked-up and Intermediate-3 stock solution in TBME was directly used for this step. After step 3, the isolated yield for 3 steps has been improved from 69% to 76% with cp >98%.

Step 4. This is a de-Boc reaction, the 4 HCl in dioxane was used for this deprotection with high purity (>99.3%).

Step 5. Coupling reaction using T3P as reagent, in order ensure the chemical purity (>99%)

Step 6. After the hydrolysis with LiOH/H2O/MeOH yield 94% with cp >99%.

Step 7. The conversion has been greatly improved from 65-75% to >98%. The additional

installments of the coupling reagent becomes unnecessary. The usage of organic base has been totally eliminated. Flash column isolation/purification has been removed. The reslurry from organic solvent system is sufficient to isolate and purify the product. The isolated yield has been improved greatly from <60% to 90% with cp >94%.

Step 8. Three different acids had been evaluated at the beginning, for the de-Boc protection reaction, HCl in dioxane, HCl in IPA and HCl in Et2O, the results were not highly satisfied in terms of the purity, color and the yield. Eventually, a new, more economic system, HCl aq. with acetone had been found to be much better than other 3 acid systems. The product was directly isolated by adding TBME and filtration as a free-flow, white solid. The crude purified by slurrying in THF provided the white solid product in >85% yield with >97% chemical purity.

Step 9. Comprehensive investigation ha been performed by PGS for this step with great success. A much better process has been developed by PGS, with yield >69% and cp >98.5% (nice white powder solid) in this step. The flash column purification has been removed.

Areal recrystallization process has been developed by PGS. Previously no solvents system had been identified as an effective recrystallization solvent for this API. The chemical purify has been enriched to 99-99.4% in the first time (as a small needle crystalline solid).

The overall yield has been increased from 8% to 33.8%, final API chemical purity from <97% to >99%.

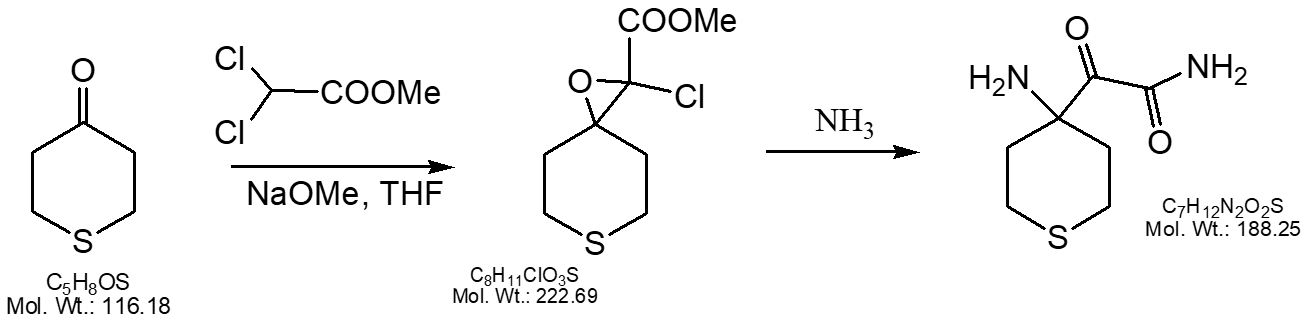

Major Improvements on the Side-Chain

Step 1. The procedure was simplified significantly, the flash column isolation/purification were removed, the crude product was used directly.

Step 2. Highly tedious operations (acid-base washes have been eliminated), simple filtration and washing with water resulted in pure product. The NH3/MeOH solution was replaced by normal ammonium aqueous solution. The overall yield has been nearly doubled from 35% to >70% with high purity. This produced via the improved protocol has been used many times for Step 7 operation. The conversion was nearly 100% for both NXT5834-8 (99.4% by HPLC).

- List Item #1

- List Item #2

- List Item #3